RFID Technology: The Future of Industrial Automation

Radio Frequency Identification (RFID) is a technology that uses electromagnetic fields to automatically identify and track tags attached to objects. This technology is not new, but its application in industrial automation has seen a renaissance thanks to its flexibility, reliability, and ability to drive efficiency and innovation.

In industrial automation, RFID technology is particularly interesting due to its ability to wirelessly communicate data between an object and a reading system, which can improve production flows, supply chains, and maintenance processes.

Tracking and data collection with RFID have a number of optimization potentials:

- Identification of the physical location of raw materials

- Access to real-time data on current production times

- Overview of who or which tool has handled the production?

- Quick localization of goods in stock with reading

- Fewer manual errors

- Data follows the individual product/tag

Simply put, fewer errors in the entire logistics and production chain.

One of the key players in the development and implementation of RFID solutions within the industry is Turck. Turck has introduced a range of innovative RFID products that support the needs of industrial automation:

Integration in challenging environments

Turck’s IP67 RFID interface highlights the technology's robustness and ability to operate in demanding environments. This product makes the integration of RFID into industrial automation both simpler and more effective, even under tough conditions often found in factories and on production lines.

IIoT and RFID: a smart combination

The integration of RFID technology with Industrial Internet of Things (IIoT) features, as demonstrated in Turck’s RFID interfaces with OPC UA server, extends the use of RFID from simple tracking to advanced data collection and analysis. This opens up new opportunities to improve efficiency, reduce costs, and increase transparency throughout the value chain.

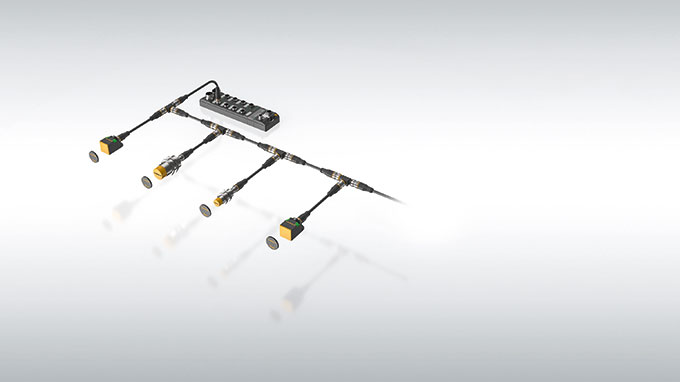

Accuracy and flexibility with IO-Link

By combining RFID technology with IO-Link communication, Turck offers solutions that provide better control and flexibility over data collection and management. This is particularly important for applications requiring precision, where accuracy and adaptability are crucial.

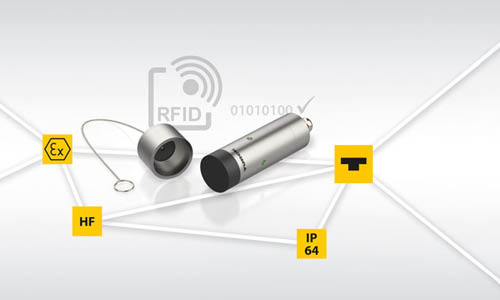

Safe use in explosive environments

Turck has also developed RFID read/write heads designed for use in explosive areas (Ex Zone 1/21), demonstrating the technology's safety aspects and its applicability in potentially hazardous industrial areas. This underscores RFID technology’s versatility and its ability to meet specific industrial safety requirements.

Speed and Efficiency with EtherCAT

To meet the need for fast real-time data transfer, Turck has introduced an RFID I/O module designed for EtherCAT, known for its high speed and efficiency in communication. This is crucial for applications requiring quick identification and tracking.

Extra compact RFID components

Finally, Turck has addressed the need for compact solutions by developing miniature RFID read/write heads and tags. These smaller units extend the usability of RFID technology to applications where space is limited, without compromising performance.

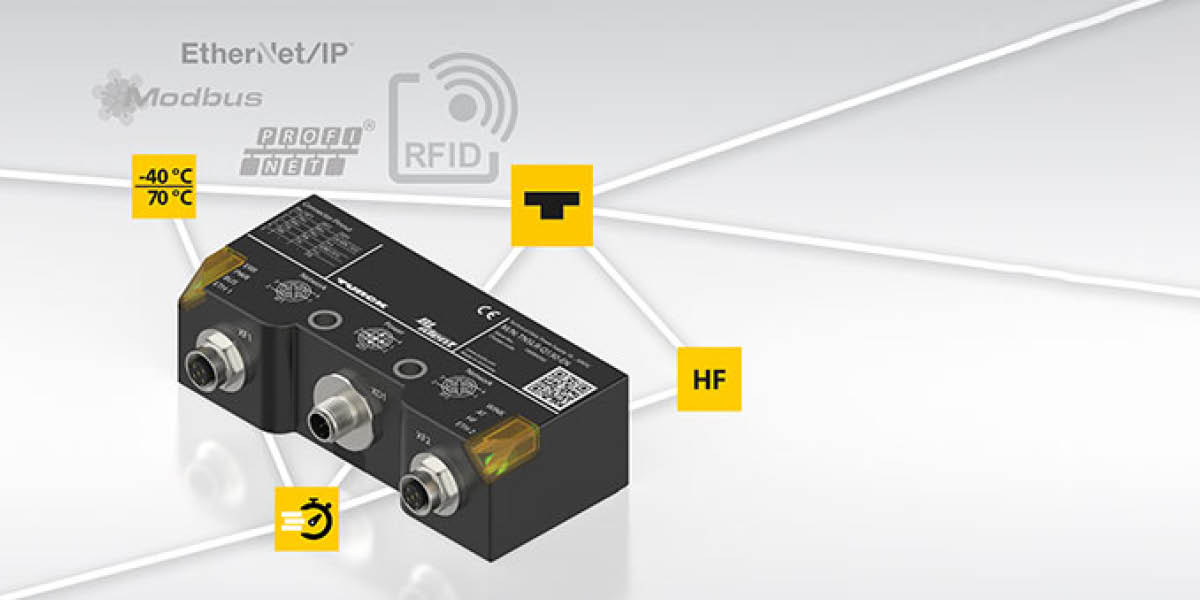

Compact design and enhanced reliability when continuous operation is critical

Turck’s new HF read/write head has direct Fieldbus communication and a very compact design. This makes it an attractive alternative where space is tight, e.g., in AVG solutions. With S2 system redundancy, enhanced reliability and data protection in RFID solutions are achieved. This feature is essential in industrial applications where data loss or system failure can cause major disruptions. S2 redundancy ensures that if part of the system fails, the other can take over without functional failure, providing continuous operation and minimizing downtime in RFID tracking and data capture scenarios.

RFID is a key component in a more connected future

RFID technology plays a critical role in the continued development of industrial automation by offering reliable, flexible, and efficient tracking and data collection. Through innovations from companies like Turck, this technology is becoming increasingly integrated into modern production and supply chain processes, opening up new opportunities for streamlining and optimization. With RFID as a key component, industrial automation is moving toward a more connected, intelligent, and flexible future.

To learn more about the great potential of RFID technology, read more about RFID for Pharma, Production, and Logistics, or contact our expert Palle Nielsen at +45 43 20 86 35 or psh@folsgaard.com.