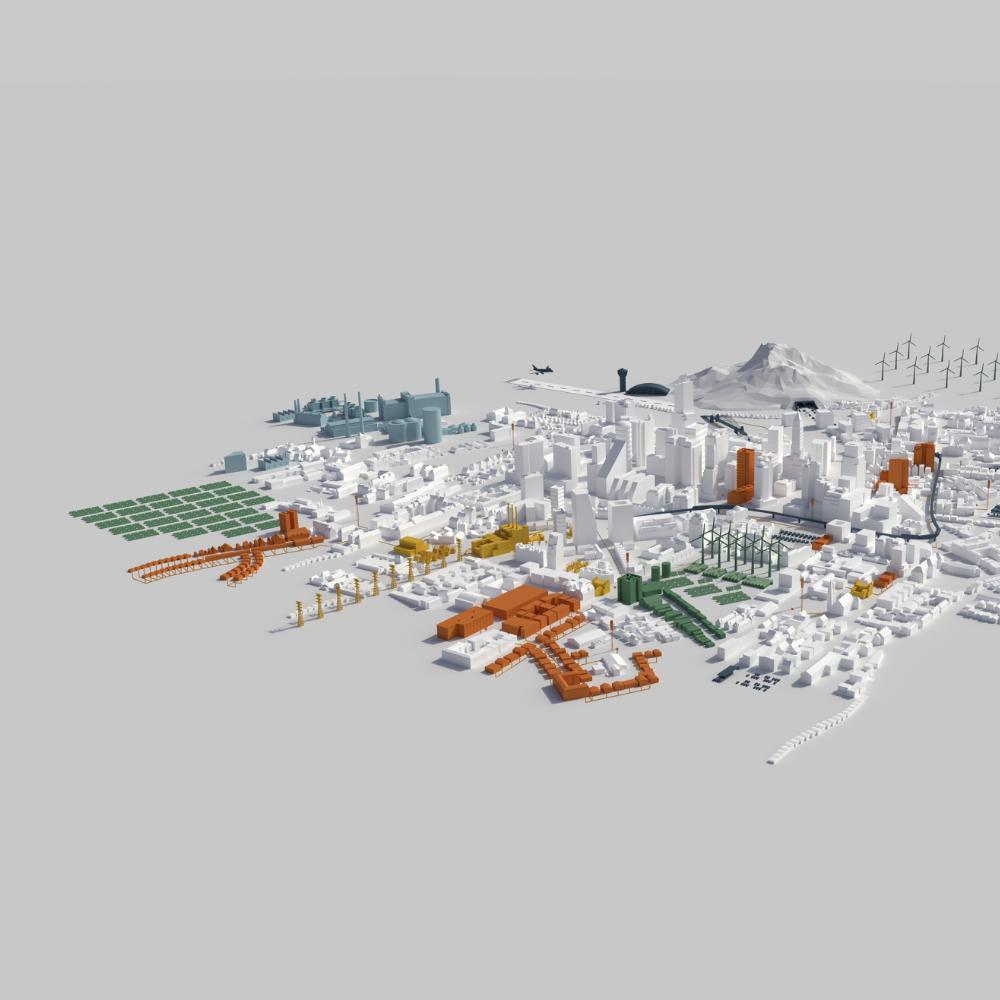

For the thousands of motorists who travel the stretch between Storhove and Øyer every day, the motorway expansion will mean more than shorter travel times. It is about safety, operational stability, and solutions that will last for many years to come.

Integration in The Supply Chain

Behind the large machines and cast concrete walls lies an extensive technical system that makes the tunnels work. Installations for power supply, lighting, ventilation, and monitoring are essential for ensuring that motorists can pass safely through the facility. For this reason, the project’s technical contractor chose to consolidate the supply of cables and cable ladders with one partner.

The Norwegian company Aventi is responsible for the tunnel technology on the section. As a total supplier within electrical, automation, and digital infrastructure, they work with the technical installations that are crucial for tunnels to operate safely in practice.

For this project, Aventi selected Følsgaard AS as the supplier of cables and cable ladders. The choice was not only about price, but also about the ability to consolidate the delivery in one place and obtain solutions adapted to a demanding tunnel environment.

Vidar Urdahl, Project Sales Manager of Aventi explains: “We wanted a partner who could deliver more than just products. The combination of quality, price, and technical understanding made it possible for us to stay on schedule and meet

safety requirements.”

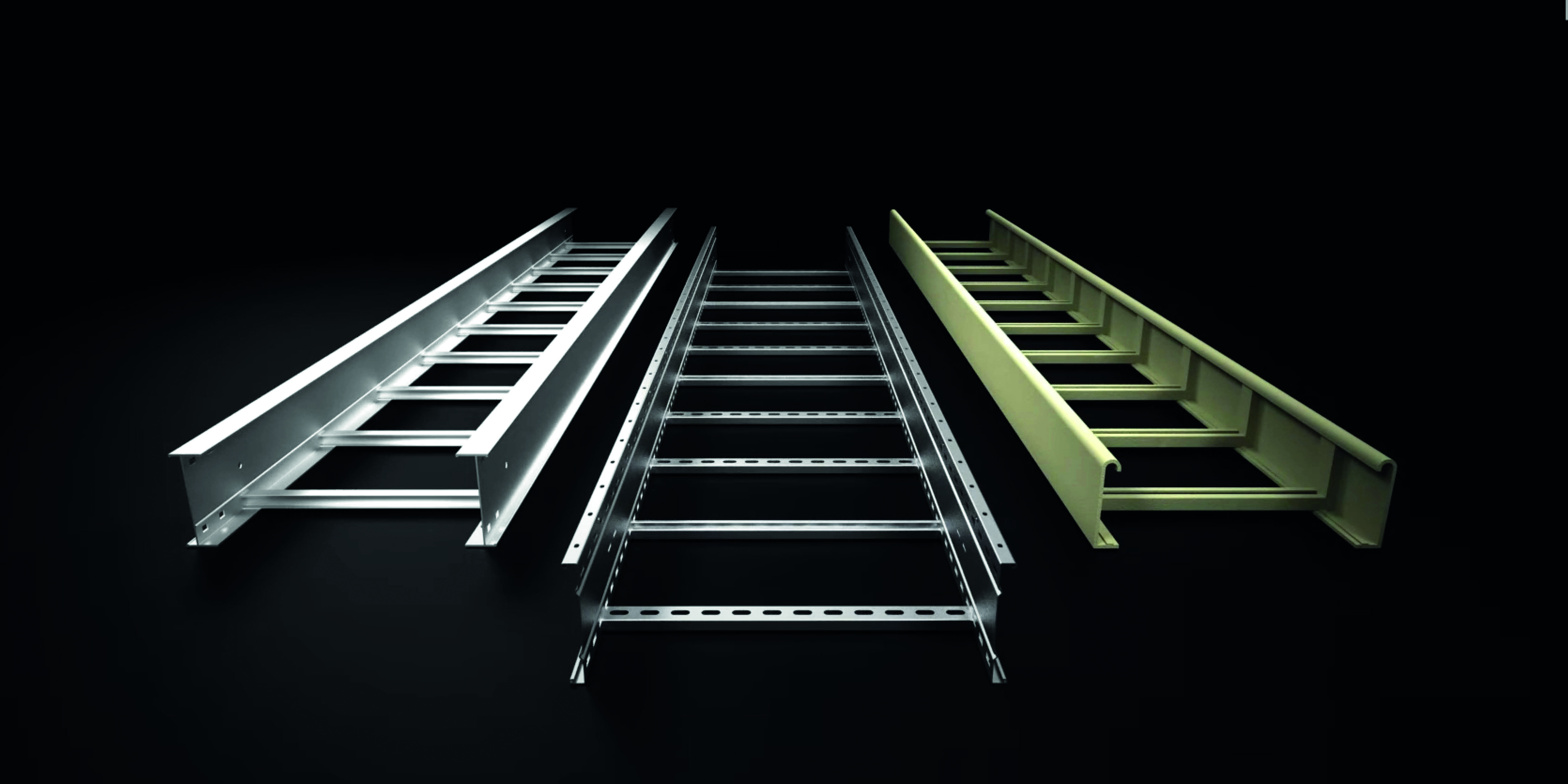

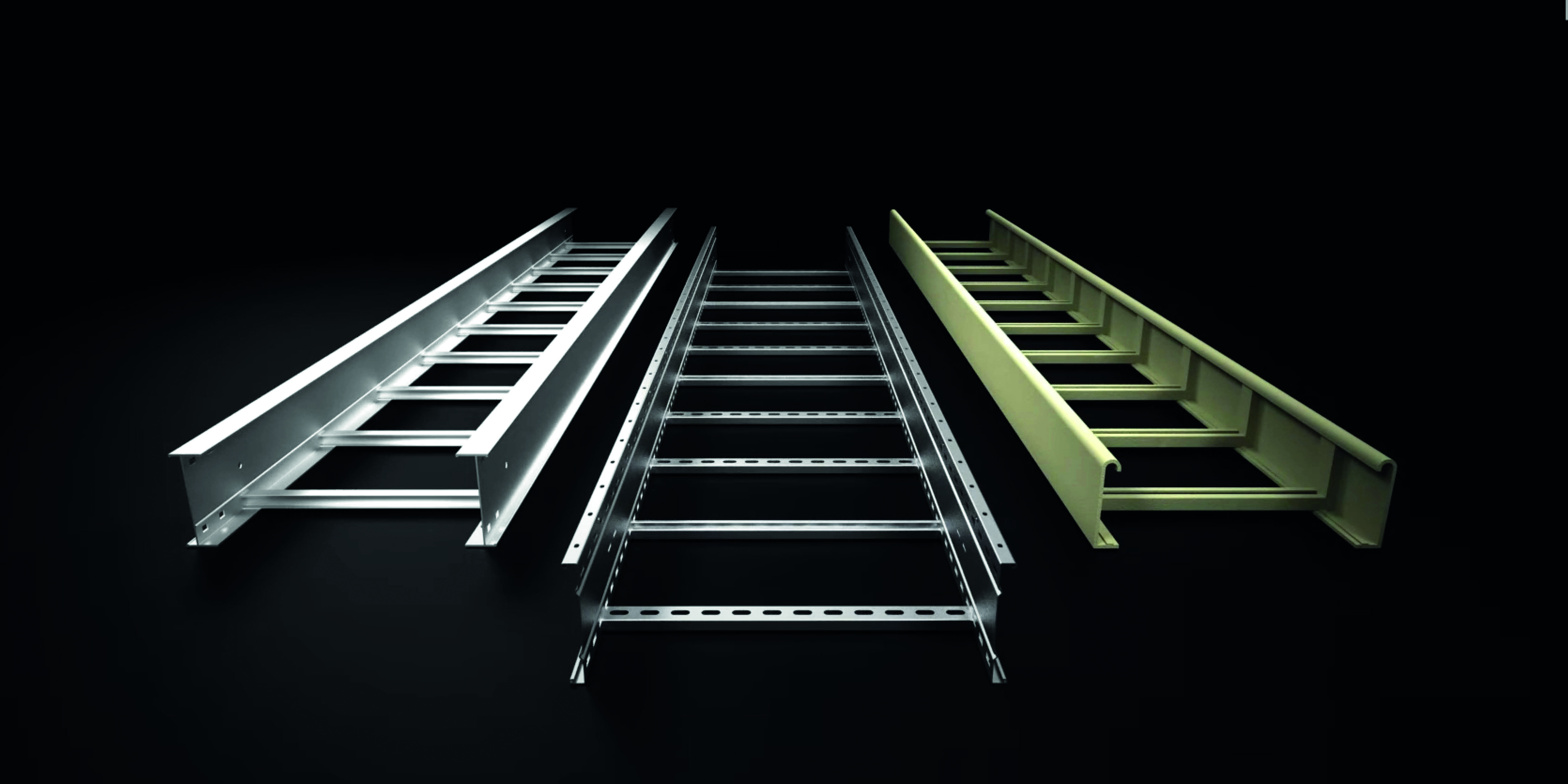

Solutions for a Demanding Environment

A tunnel environment places specific demands on technical installations. The cables

must withstand moisture and temperature fluctuations, while the cable ladders must

carry heavy loads and still be easy to service. The focus here was on selecting solutions that provide high reliability and low maintenance – benefitting both the contractor and the road user.

"It is clear that long-term operation and durability were considered. That means we can focus on stable operations rather than ongoing repairs”

Reduce On-Site Complexity with Customized Bracket Solution

In line with its customer-focused engineering approach, Følsgaard has developed a range of tailored solutions that address practical challenges in the installation of auxiliary equipment on cable management systems. For instance, surveillance cameras and similar devices can often be difficult to mount securely and efficiently at height.

To solve this, Følsgaard has designed dedicated bracket systems that allow equipment to be pre-mounted at ground level under controlled conditions and subsequently fixed onto the cable ladder in a single, simplified step.

This not only minimizes installation time and reduces on-site complexity but also enhances both safety and quality assurance during assembly.

In addition, Følsgaard supplies customized frame structures for control rooms to facilitate the reliable mounting of cabinets. These frames are engineered to integrate seamlessly with project-specific layouts and technical requirements.

All solutions are developed in close collaboration with clients’ engineering teams, enabling precise alignment with operational needs and reflecting Følsgaard’s commitment to delivering robust, reliable, and application-specific designs.

Joint Innovation in Tunnel Safety

The project is part of the framework of the collaboration group Smartere Tunneler (“Smarter Tunnels”). Here, suppliers work together with Nye Veier, the Norwegian Public Roads Administration, and the county authorities to develop solutions that make tunnels safer, easier to maintain, and more cost-effective.

"It gives us confidence to know that our suppliers are part of a professional environment where innovation and knowledge-sharing are central" says the Project Sales Manager. For the project, this has meant access to some of the most modern and proven solutions available.

TCO in Focus

The E6 Storhove–Øyer project is a good example of how major infrastructure projects are increasingly evaluated on more than just construction costs. Long service life, low operating costs, and a reduced environmental footprint are just as important.

“Future projects will place even greater emphasis on reliability, sustainability, and total cost of ownership. It is a development we already see taking shape here”, concludes Vidar Urdahl.

The Sum of Experience

The project at Storhove and Øyer illustrates that solid cable and installation solutions can be just as decisive as asphalt and concrete when it comes to ensuring that a tunnel operates safely for decades.

The collaboration between contractors, suppliers, and authorities demonstrates how a holistic perspective can be turned into tangible value for both motorists and society.

As Terje Humlebrek, Key Account Manager at Følsgaard, summarizes:

“It is not just about delivering products, but about contributing experience and solutions that create lasting value – for the project and for the people who will use the tunnel.”